Ford Improves Productivity with TigerGraph

Ford Motor Company is one of the largest automakers in the world, with revenues of almost $130 billion in 2020.

The Challenge

Ford used two relational databases to store and analyze the data collected from its machinery, but quickly ran into problems with data ambiguity that resulted in production downtimes.

The Solution

Ford decided to complement its relational databases with a graph database, initially to remove data duplicates using entity resolution – this was a challenge that Ford had been trying to address for many months.

The Results

Ford is now able to reconcile data in each of its two databases to the same piece of the production line machinery with 90% accuracy.

By 2020, 50% of motor vehicle manufacturers will apply advanced analytics to connected-vehicle data to identify and correct product defects.

The Challenge

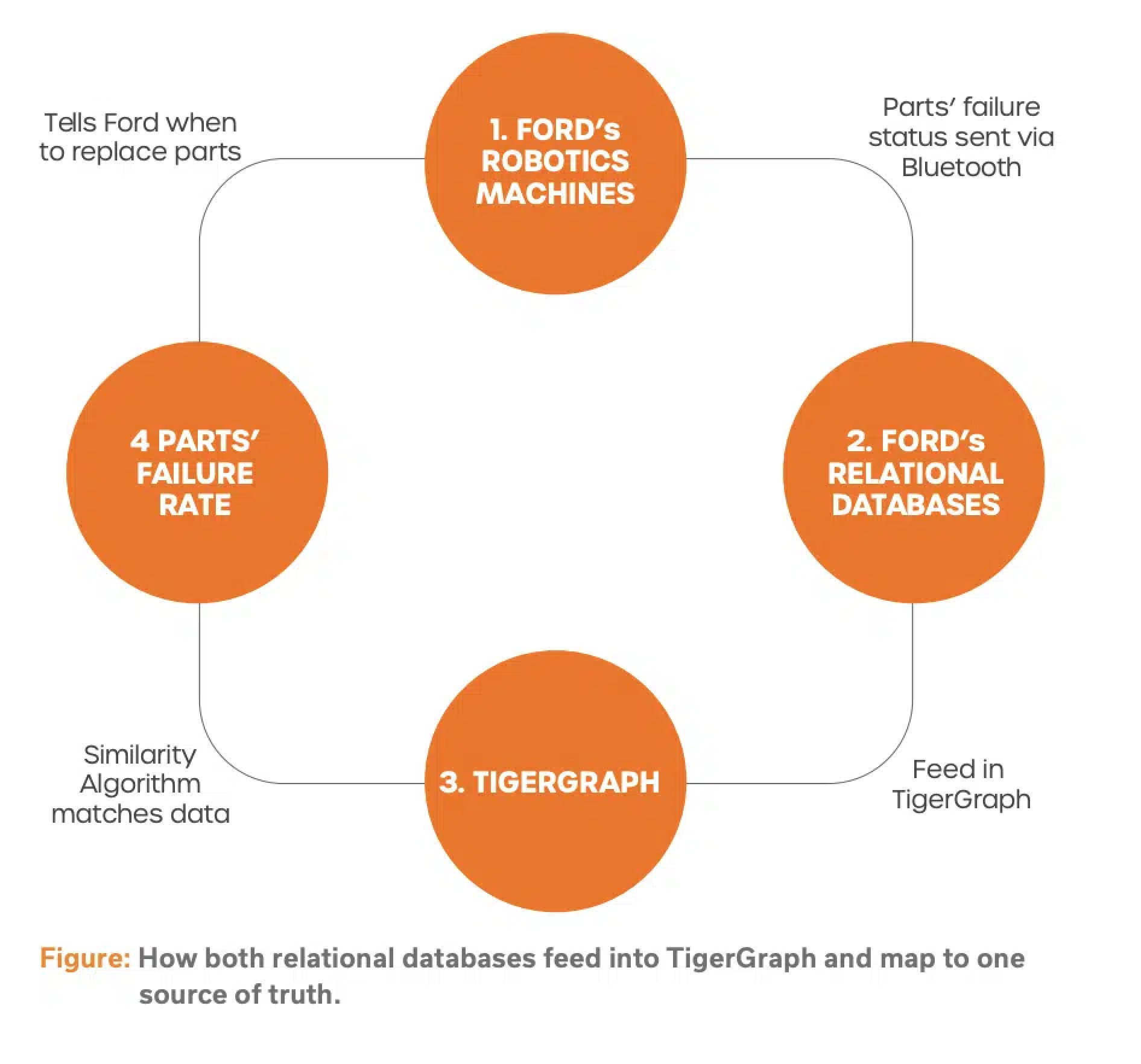

Ford uses the internet of things to remotely manage its manufacturing equipment around the world – this machinery performs a variety of production tasks including welding, painting, assembly, and more. Ford used two relational databases to store and analyze the data collected from its machinery, but quickly ran into problems with data ambiguity that resulted in production downtimes. The company realized they needed an entity resolution system to consolidate their data.

The Solution

Ford decided to complement its relational databases with a graph database, initially to remove data duplicates using entity resolution – this was a challenge that Ford had been trying to address for many months. Once data ambiguities were removed, similarity matching algorithms were applied to maximize production uptimes. Using TigerGraph, they could identify which robotic parts were about to fail so they could replace the failing parts all at once, thereby optimizing their production efficiency.

The Results

Ford is now able to reconcile data in each of its two databases to the same piece of the production line machinery with 90% accuracy. Since using TigerGraph’s entity resolution for asset tag reconciliation, they’re able to identify when a part is about to fail so they can pre-plan and avoid unnecessary breaks in the production assembly line.

The data sciences team at Amgen is now able to support its colleagues in marketing and branding with the insights they need about the referral networks and influential doctors and ensures everyone is fully informed about the medicines that can positively affect the quality of care of millions of patients.

The data sciences team at Amgen is now able to support its colleagues in marketing and branding with the insights they need about the referral networks and influential doctors and ensures everyone is fully informed about the medicines that can positively affect the quality of care of millions of patients.

Ready to Harness the Power of Connected Data?

Start your journey with TigerGraph today!